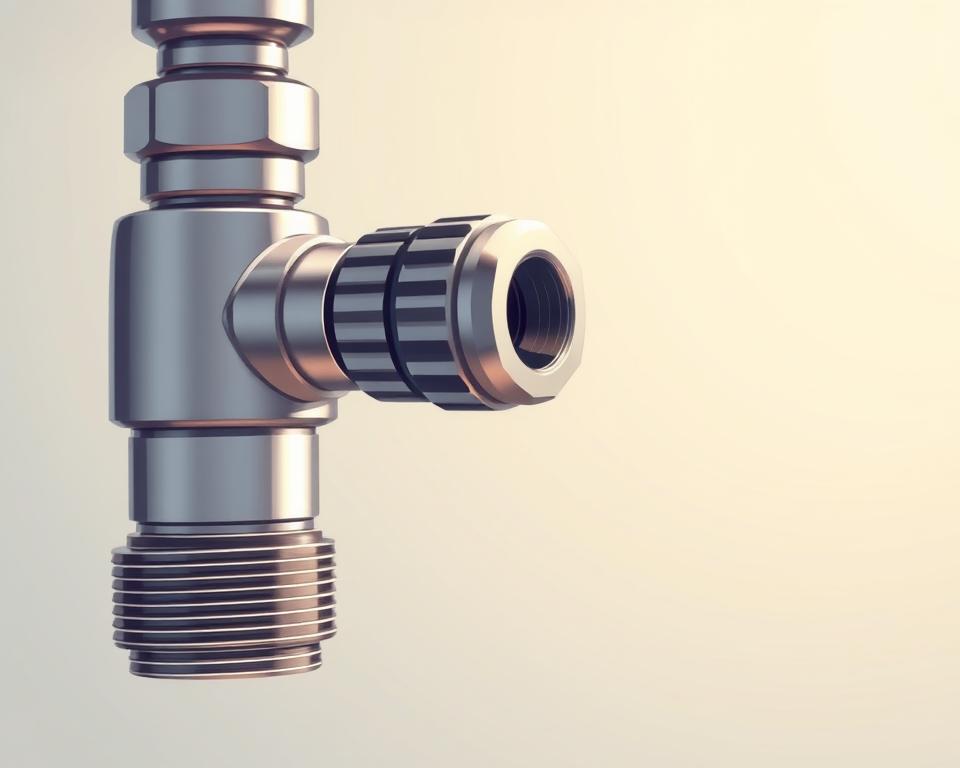

Installation Parts Supply – Brass Forged Compression Tee Fittings

Did you realize more than 60% of plumbing breakdowns stem from subpar connections? Hence, picking the proper 1/2 t fitting components is essential. Installation Parts Supply delivers commercial-grade fixes engineered for lasting performance.

Our compression T-fittings use top-grade CA360/CA377 brass for toughness in low–medium pressure setups. They meet ASA, ASME & SAE specs when you use them with copper, aluminum, or thermoplastic tube.

Great in non-moving setups: not for steel pipe yet outstanding where vibration is minimal. Plus, with inventory clearance sales, you get top-tier quality without delays.

Premium Compression Tee Brass Forged Fittings for Reliable Plumbing

Hydraulic setups require exacting components for enduring operation. Our brass compression solutions feature a two-ferrule assembly, keeping joints sealed under shaking.

The dual-ferrule mechanism holds the tube tight, minimizing leaks at high pressure. Compared to single-ferrule types, it spreads force uniformly, perfect for brake lines and industrial machines.

| Feature | Single-Ferrule | Double-Ferrule |

|---|---|---|

| Shake Tolerance | Moderate | High |

| Pressure Capacity | Low | Medium |

| Fluid Compatibility | Basic liquids | Hydraulic fluids, coolants |

These compression connectors work with liquids including coolants and greases. When using gases, choose JIC flare fittings to improve safety.

From heavy machinery to automotive systems, our brass compression fittings deliver unmatched reliability. They’re built to handle the toughest industrial challenges.

Key Features of Our Brass Compression Tee Fittings

Reliable seals begin with superior parts—discover our advantages.

Crafted via forging, this premium brass resists wear more than cast fittings. The dense structure resists cracks, ensuring longevity in water and glycol systems.

Precision-machined threads create airtight seals, even under pressure. Tapered nuts bite harder under load, cutting leaks in crucial lines.

- Interchangeable: Combine with 45° or 90° elbows for versatile routing.

- Reducing tees: Connect mixed tubing sizes seamlessly.

- Corrosion-resistant: Perfect in tough settings such as HVAC or marine.

Connecting copper? They clamp tight—no solder needed. We also stock needle valves and bleed accessories for complete system control.

Versatile Applications Across Industries

In factories to ocean rigs, dependable fittings are key. They perform leak-free in many settings, even under high load.

HVAC systems rely on these parts for refrigerant *pipe* lines.|In HVAC, they handle refrigerant pipes.|Used in HVAC systems for refrigerant piping. Rustproof brass holds up to thermal changes, great for rooftop and chiller setups.

In food processing plants, sanitation is critical.|Food plants demand hygiene. These *male* adapters connect stainless steel tubing, meeting USDA standards. Plastic *tube* inserts prevent cracking in washdown areas.

Marine applications demand durability.|At sea, toughness is non-negotiable. Sea-resistant brass guards ship and rig hydraulics. Pair with *flare fittings* for high-pressure fuel lines.

- Manufacturing: Supports presses and CNCs via tight compression seals.

- Pneumatic Tools: Lightweight yet sturdy for assembly lines and automotive shops.

- Instrumentation: JIC-grade fitting for precise instrument readings.

Replace threaded flare parts on the fly. From production lines to trawlers, they adapt perfectly.

Why Choose Installation Parts Supply for Your Fittings?

Looking for rugged plumbing fittings with no fuss? We deliver high-quality brass components backed by direct manufacturer support. Call 866-515-5481 or email for tailored help.

Our compression fittings undergo rigorous quality checks—from forging to packaging.|We test every compression fitting from forge to box.|Every fitting is inspected from stamping to shipping. Custom length? We can machine to your drawing.

Save with inventory clearance sales and bulk pricing.|Cut costs via clearance sales and volume discounts.|Get deals with clearance and bulk rates. Add valves or adapters for a turnkey upgrade. Expedited shipping ensures you meet tight deadlines.

Join our newsletter for exclusive deals on industrial fittings. Trust a partner who prioritizes your project’s success.

FAQ

Which sectors often employ brass compression tee fittings?

Common in plumbing, heating/cooling, and gas work for their strength and leak resistance.

What’s the best way to get a leak-free seal?

Prep the pipe ends, align fittings, and snug the nut evenly for no leaks.

Can these fittings handle high-pressure systems?

Indeed, forged brass build means they stand up to moderate and high pressures.

Can they be used on different tube types?

They seal on copper, PEX, etc., when you add matching sleeves.

What sets these fittings apart?

Our CNC-finished parts resist corrosion and pass strict QC.

Do you provide custom sizing options?

Certainly—we produce custom configs to fit your project.